Table Of Content

- What Device Makers Need To Know About Design Verification and Validation

- Bonus Podcast Episode about Design Verification & Validation

- EVT: The Engineering Validation Test

- Keep all your design control activities in one centralized location with Greenlight Guru

- What is design verification?

- Explore AI Writing Tools: A Quick Guide

- Design verification as per FDA requirements

Our data driven decisions are taken with results in mind, and we are determined to ensure they deliver. We pride ourselves on delivering three key differences, no matter the project. Our expertise in brand strategy and meticulous web redesign helped Rollink boost its online presence. Our services target growth for all businesses, no matter the industry or size. Our team imagine and implement on-brand visuals to increase physical conversions and brand recognition.

What Device Makers Need To Know About Design Verification and Validation

M3 Pro And M3 Max MacBook Pro Models Could Launch Alongside M3 MacBook Air Next Year As Devices Reach Design Validation Testing - Wccftech

M3 Pro And M3 Max MacBook Pro Models Could Launch Alongside M3 MacBook Air Next Year As Devices Reach Design Validation Testing.

Posted: Mon, 16 Oct 2023 07:00:00 GMT [source]

Design validation is of utmost importance as it is the best way to ensure that the design meets the needs of both the user and the business. Before a new app is developed, the design of the app should be validated by testing it with users to ensure that it solves the intended problem. Aligning users’ needs and expectations with the design is the best way to ensure that the product will be of service to its intended audience and a great predictor of the product’s success in the market. For example, an end-to-end graphic design project that includes print materials, brand designs and custom web designs will be much more expensive than a one-off packaging design service.

Bonus Podcast Episode about Design Verification & Validation

It typically starts at a minimum quantity of 5,000 units but can lead up to several million units in the case of popular consumer products such as the PlayStation, iPad, iPhone, or the Rubik’s cube. A prototype is an instantiation of a product design that can be used to communicate and assess its value regarding certain requirements. Prototypes range from low-fidelity ‘soft’ models handmade of materials such as clay, cardboard, foam, and wood to high-fidelity functional prototypes 3D printed or made in the machine shop. When a prototype incorporates all requirements and functionalities with the design, it is called the engineering prototype. As the process advances towards production, the cost of these iterations rises exponentially. Tooling changes in the production phase may lead up to $50,000 in total cost and result in multiple weeks or months of delay.

EVT: The Engineering Validation Test

This distribution should ideally coincide with the information architecture and hierarchy you’re going for. Take a look at the gif below to get a better idea of what we’re talking about. This list of design validation methods presented in this article is by no means comprehensive. Service design can help our organizations innovate customer experience and build brand loyalty — and it’s great for small businesses.

Keep all your design control activities in one centralized location with Greenlight Guru

However, their focus on speed often leads to neglecting validation and basing decisions off of assumptions to save time. Unfortunately, this false belief can lead to even more time wasted after the product is released, due to a lack of market research. Validation enables designers to identify and understand the right areas to focus on.

Ensure all your test results, observations, and deviations are documented. Every project must work with a schedule to ensure its implementation does not affect other aspects of product development. Create a detailed design validation schedule with an outline of when each activity will happen, the person or team responsible, and the resources needed. Design validation can be a complex process so having a plan is crucial.

Explore AI Writing Tools: A Quick Guide

While verification focuses on verifying device specifications, medical device design validation ensures user needs and intended uses are met. Instead of verifying a specific part of the device’s design is correct, validation tests the device as a whole, with particular attention paid to the user’s interactions with the device. Recapping the phases of product maturity, the goal of the POC and prototyping phases is to verify that the product concept is viable, people have a need for it, and that it’s possible to develop it.

Wison New Energies awarded FLNG design and EPC contract - LNG Industry

Wison New Energies awarded FLNG design and EPC contract.

Posted: Tue, 23 Jan 2024 08:00:00 GMT [source]

Design verification as per FDA requirements

Documentation is crucial for traceability and meeting product compliance. In the sphere of product development and manufacturing, design validation is often overlooked despite being one of the crucial aspects. Design validation plans (DVP) have a crucial role in ensuring that the product flawlessly adheres to all the specifications and functions. As briefly mentioned in the design validation process outline, goals need to be specific and measurable. In the shopping cart example, a SMART objective would be to lower the number of users that abandon their cart by 9% within the next business quarter. Moreover, the use of statistical techniques in the verification and validation processes adds an additional layer of rigor and objectivity.

The design validation plan is a step-by-step approach to conducting a thorough design validation serving as the roadmap for the validation process. Airbnb conducted a thorough design validation that led to the new mobile redesign. This methodology includes getting users to complete certain tasks on your website or app while you are recording their behavior.

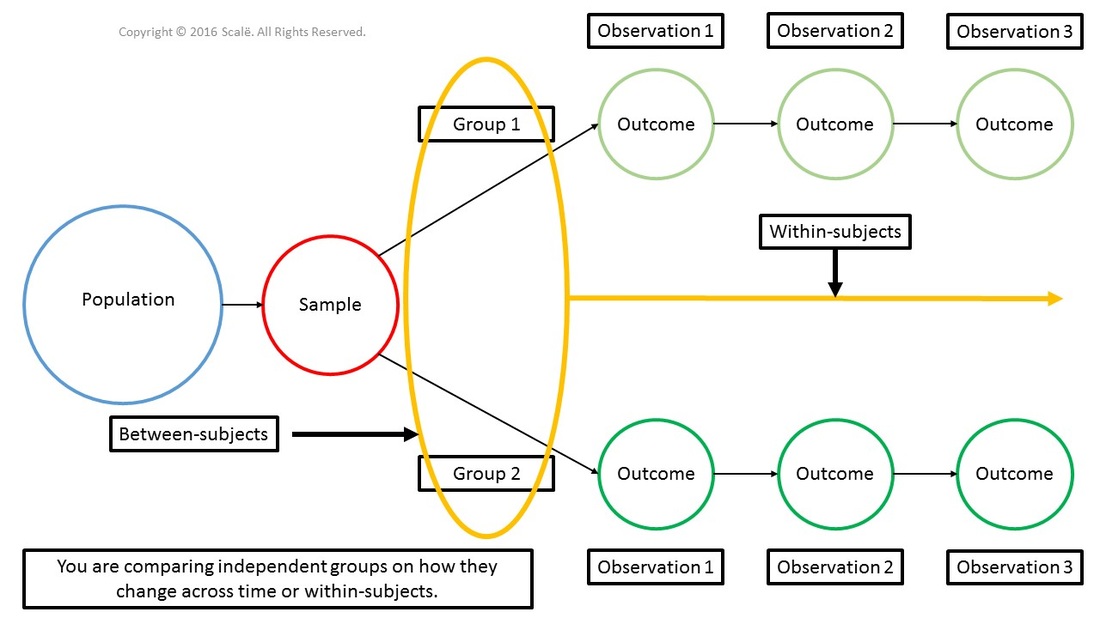

Combining these, we can implement the know-how and the passion that is necessary to create graphic designs that extend brand awareness and credibility. Bring your brand to life with physical graphic designs that help your marketing collateral reach an audience that converts. How long you take in each stage determines when you can mass produce your product. However, each stage is essential, and missing any details or making wrong decisions can reduce yield, increase manufacturing costs and lengthy delays. Develop clear, specific research questions and hypotheses based on key user needs or observations you’ve made on your site. With split testing methods, you divide users into two or more groups and provide each group with a different version of a product page or website element.

As a rule of thumb, the further along a product is in development, the more costly it becomes to make changes. Hence, a key overarching goal of any product development initiative is to resolve issues early, reducing the risk of costly iterations at subsequent stages. There is an art to writing design inputs, and the way you go about it will be a major factor in how effective your verification process is. Validation is the step where you actually build a version of the product, and would be done against the requirements as modified after verification. Once you decide what representative product you will build to prove the design, you fully test it to make sure that the product, as designed, will meet all the necessary requirements defined in the Design Inputs. ISO 9001 Design Verification and Design Validation are two steps that are distinctly different, and important in a good design process.

One step is used to make sure that the design has addressed every requirement, while the other is used to prove that the design can meet the requirements set out for it. Let’s kick off this list with the trusty old favorite - usability testing. This method is based on the axiom that design without users is not design, i.e. every major design decision should be validated by the means of testing it on actual users. Sometimes, products are born as solutions without a problem in mind because someone neglected validation. If there isn’t enough market demand or demand for a product at a certain price point, then the business is at risk because no one validated its assumptions early on. More often than not, design verification involves suites of tests and trials.

It’s easy to confuse the two because they both involve checking an outcome against your previous specifications. Most product development teams rarely consider stakeholder interviews as a method of design validation. But the truth is, that stakeholders (anyone with an impact on product design) are key players in the design of a product. Therefore, interviewing them can provide essential feedback about the design.

They also run a quality assurance, QA, and quality control, QC, to ensure the efficiency of your supply chain. For example, if your surgical instrument is supposed to be 12 inches long, you should produce an instrument that’s representative of your final product, measure it, and ensure it is the correct length. The same process applies to an instrument that is designed to meet a specific torque specification. To verify this, you would run a test on a statistically valid sample size that applies rotational force and ensure that it can handle that torque level. Approximately 20 to 50 units are produced using high-precision processes such as additive manufacturing and CNC machining, or a series of casts based on soft tooling such as silicone or 3D printed molds. The overall objective is to develop the design with full production intent and end up with a small number of production-worthy engineering prototypes.

No comments:

Post a Comment